Bending metal with press brakes is a common method used in metal fabrication to achieve precise and accurate bends. The process involves using a press brake machine, which consists of a hydraulic or mechanical press and a set of dies. Here are the general steps involved in bending metal with press brakes:

Material Preparation: Start by selecting the appropriate metal sheet or plate for your project. Ensure that it is clean and free from any contaminants.

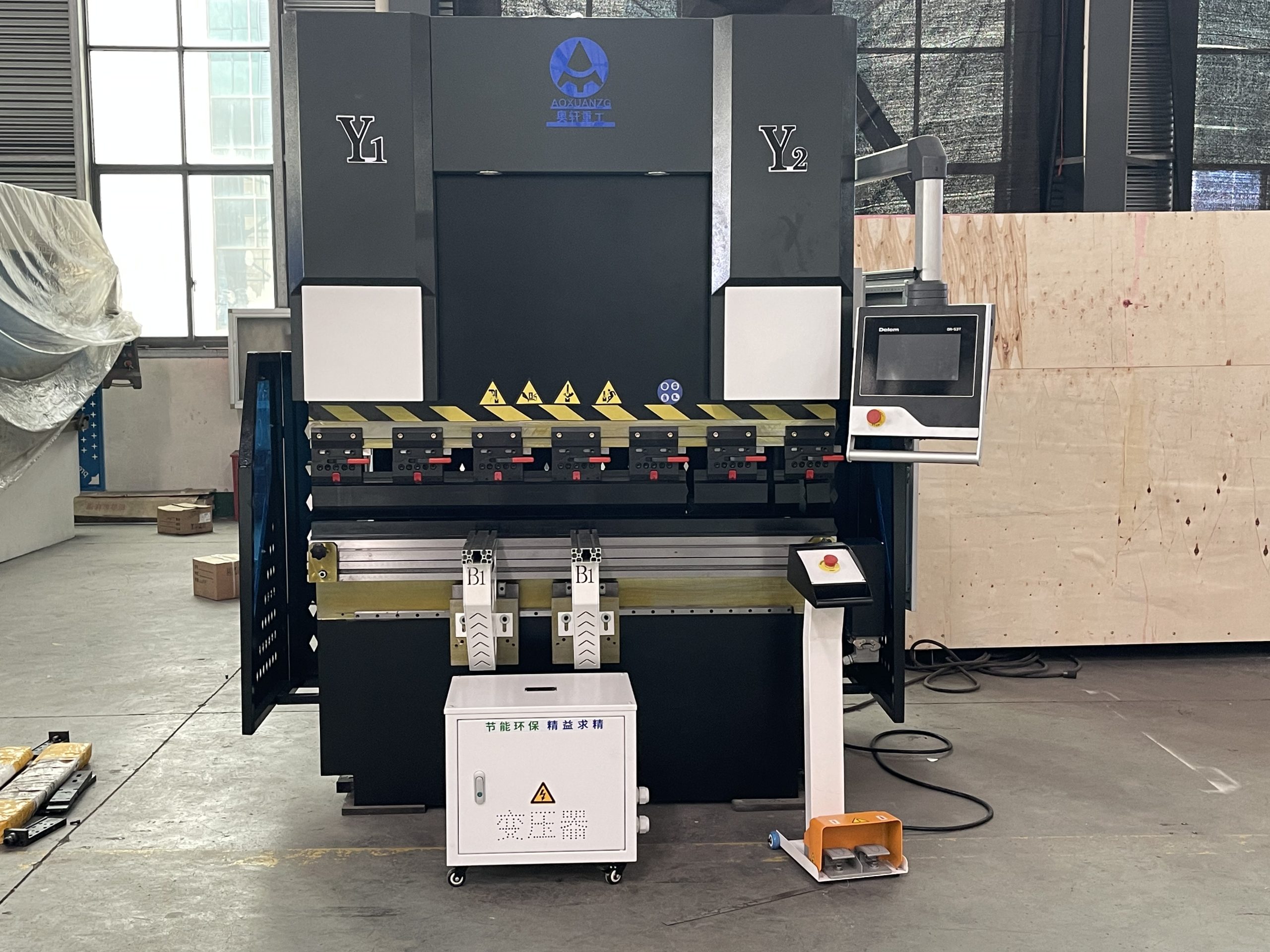

Set Up the Press Brake: Adjust the press brake machine according to the specifications of the metal sheet, including the desired bend angle and bend radius. This involves positioning the bottom die (also known as the V-die) and the top punch, which will shape the metal.

Load the Metal Sheet: Place the metal sheet onto the press brake’s bed, ensuring proper alignment with the dies. Use clamps or other fixtures to secure the sheet in place.

Position the Back Gauge: The back gauge is a device that helps position the metal sheet accurately for each bend. Adjust the back gauge to the desired distance from the bend line, ensuring consistent bends throughout the process.

Bend the Metal: Activate the press brake machine, which applies force to the metal sheet through the top punch. The force causes the metal to deform and bend along the V-die. The bending process may involve multiple passes, depending on the thickness and hardness of the metal.

Check the Bend Angle: After each bend, use a protractor or angle gauge to measure the bend angle and ensure it matches the desired specifications. Make adjustments to the machine if necessary.

Repeat the Process: If your project requires multiple bends, reposition the metal sheet, adjust the back gauge, and repeat the bending process for each bend until the desired shape is achieved.

Unload the Bent Metal: Once all the bends are complete, carefully remove the bent metal sheet from the press brake machine. Be cautious as the metal may still be hot or sharp.

It is important to note that the specific steps and settings may vary depending on the type and model of the press brake machine being used, as well as the characteristics of the metal being bent. It is recommended to follow the manufacturer’s instructions and guidelines for your specific press brake machine to ensure safe and accurate bending operations.