Hydraulic sheet metal shearing machine is a frequently used shearing machine in metal processing industry. Owing to its

outstanding productivity and low noise, hydraulic guillotine is increasingly used by metal fabricating industries. In addition,

CNC system ensure easy operation and adjustment.

1. Hydraulic swing beam shearing machine with high resolution touch screen

2. Variable hydraulic guillotine shear for all metal sheets

3. Adjustable blade gap, cutting angle and cutting length make it possible to cut all types of metals with various

materials and thicknesses.

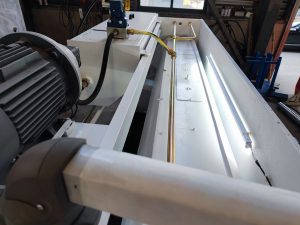

4. Blade gap adjustment is based on the material and thickness of metal sheets to be cut. Optimum gap not only effectively extend the lifespan of blade but also guarantee shearing quality. Generally, the adjustable ratio accounts

for 10% of the sheet thickness.

5. Fine adjustment of cutting angle is designed for minimum distortion of metal sheets.

6.Totally EU streamlined design,Monoblock by welding robots & aparatus and stress relief process by Annealing treatment.

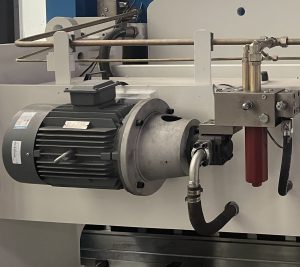

7. Adopt integrated hydraulic system, more reliable and easy for maintenance. and the hydraulic system from Bosch-Rexroth, Germany, 8. Equipped with lighting-alignment, so as to align when shearing. The stroke of knife beam can be adjusted in stepless mode.

9 Hydraulic drive, return of knife beam is smooth and prompt by nitrogen cylinder.

10. CE conformity including Tiltable Front Finger Guard and Optical Rear Safety Guard,

11. Safe fence and the electric interlocker have been designed for the machine to ensure the operation safety.