1. Excellent quality of light beam: smaller focus facula, more fine cutting line, higher working efficiency, better processing

quality.

2. Highly cutting speed: the 2 times by co2 laser cutting machine under the same power.

3. Very high stability: adopt world top imported fiber laser source , stable performance, the using life of key parts can reach up to 100 thousands hours.

4. Very high efficiency of photoelectric conversion: of which fiber laser cutting machine is 3 times by co2 laser cutting machine,saving the energy and protecting environment.

5. Very low using cost: power consumption of whole machine is only 20-30% of co2 laser cutting machine under same power.

6. Very low maintenance cost: no working gas for laser source; fiber transmission, no need the reflecting lens; can save large maintenance cost.

7. Convenient product operation and maintenance: fiber transmission, no need to adjust the optical path.

8. Very strong soft optical effects: compact volume and structure, which is easy for soft processing requirement.

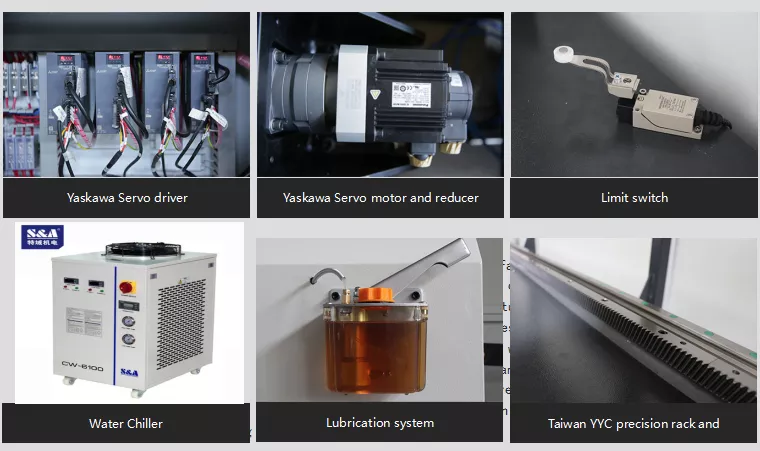

9. The machine tool adopts gantry double driving structure, high damping machine tool bed, good rigid, which can suffer very high speed and acceleration.

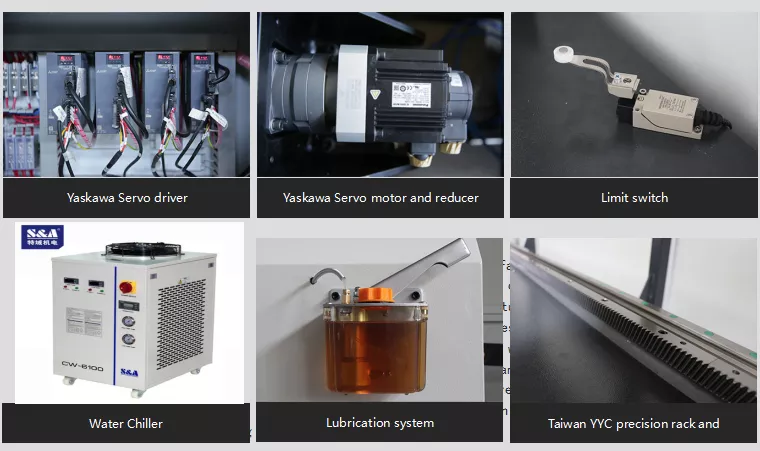

10. This model adopts imported AC servo system driver and imported transmission system, the moving structure of machine tool adopts imported gear and rack transmission, linear guide track for guiding, ensuring the high speed,high precision and high reliability of equipment.

11. Rack and guide adopt fullly enclosed protective device, which prevents oil free friction movement and dust pollution, enhances using life of transmission parts and ensures the precision of machine tool movement.

12. Professional laser cutting machine, cnc control system, computer operation, can ensure the cutting quality, and more

convenient for cutting work.