Press brake is a kind of machine specially in bending plate, mainly used in automotive manufacturing, kitchen appliance manufacturing, electricity poles, lamp posts, ship-building, military industry, steel industry, mechanical manufacturing. Bending dies can be designed and changed according to customers' different needs.

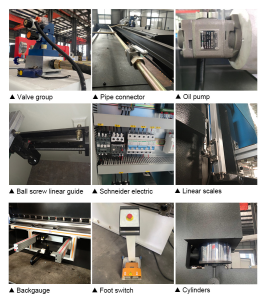

The main machine adopts the structure of series WC67Y CNC press brake;

High precision, high efficiency CNC Torsion Bar Synchro Press Brakes;

Holistic welding structure;

Stabilizes left and right balance with help of the mechanical Torsion Bar;

Backguage is drove by servo motor and performance;

Ball screw and linear guide.

This bending machine has the Bridge Automatic Bending Machine, this system can be Automatic suction, automatic bending, automatic discharging integration,this set can be more efficient, and can improve the working speed, and can be more stability.It helps to make the work automatic, simple and easily.

High precision backguage

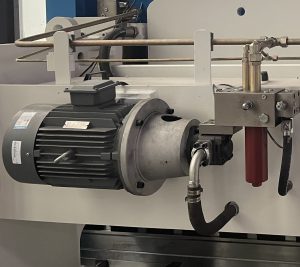

Germany Bosch Rexroth safety valve

Germany EMB Hose connector

Schneider Electric Syste

RV reducer motor working table compensation (Optional)

Compensation device on workbench (Optional

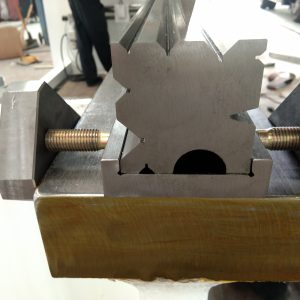

Quick mold clamping device